14

1. Instrucciones de seguridad importantes

2. Generalidades

GUARDE ESTAS INSTRUCCIONES

Todas las secciones de este manual contienen instrucciones y advertencias que deben seguirse durante la instalación y el uso de los racks

SmartRack descritos en este manual. Lea atentamente todas las instrucciones y advertencias antes de intentar mover, instalar o usar los

racks SmartRack descritos en este manual. El incumplimiento puede causar lesiones personales y daños a la propiedad y puede invalidar la

garantía.

• Mantenga el rack en un ambiente interior controlado, lejos de la humedad, temperaturas extremas, líquidos y gases inflamables, contaminantes

conductores, polvo y la luz directa del sol.

• Deje espacio suficiente en el frente y la parte trasera del rack para una ventilación adecuada. No bloquee, cubra ni inserte objetos en las aberturas de

ventilación externa del rack.

• El rack es extremadamente pesado. Manipúlelo con precaución. No intente desembalarlo, moverlo ni instalarlo sin ayuda. Use un equipo mecánico,

como una horquilla elevadora o un gato para pálets para moverlo en el contenedor de envío.

• No coloque ningún objeto sobre el rack, especialmente contenedores de líquido, y no intente apilar los racks.

• Inspeccione el contenedor de envío y el rack para detectar daños producidos durante el transporte. No lo use si está dañado

• Deje el rack en el contenedor de envío hasta que se lo haya movido lo más cerca posible del lugar de instalación. Las ruedas están diseñadas para

realizar únicamente ajustes menores de la posición dentro de la zona de instalación final. No están destinadas a mover el rack por largas distancias.

• Las ruedas no están destinadas a funcionar como soporte a largo plazo después de la instalación final. Use los niveladores para el soporte a largo plazo.

• Instale el rack en una zona estructuralmente sana, con piso nivelado que pueda soportar su peso, el de todos los equipos que se instalarán en él y

cualquier otro rack y/o equipos que se instalarán cerca.

• Instale firmemente el gabinete a la estructura del edificio, usando los soportes de embarque como se ilustra en la sección de Instalación del Gabinete

de este manual.

• No empuje el rack por los paneles laterales para moverlo. De esta manera existe peligro de que se vuelque.

• Cuando lo haga rodar sobre sus ruedas, empújelo siempre desde atrás, nunca hacia usted.

• Un rack rodante puede causar lesiones personales y daño a la propiedad si no se supervisa correctamente. Si es necesario hacerlo rodar por una rampa,

hágalo con precaución extrema. No intente usar rampas con una pendiente más pronunciada que 1:12.

• Corte el material de embalaje con precaución. El rack podría rayarse causando daños que no están cubiertos por la garantía.

• Guarde los materiales de embalaje para utilizarlos en el futuro. Si el rack se vuelve a embalar y a enviar sin los materiales de embalaje originales, se

pueden causar daños que anularán la garantía.

• No vuelva a enviar el rack con equipos adicionales, a menos que haya sido enviado con un pálet especial contra golpes (sólo los modelos “SP1”). El

peso combinador del rack y de los equipos instalados no debe exceder la capacidad de carga del pálet. Tripp Lite no se responsabiliza por ningún daño

que se produzca durante el reenvío.

• No se recomienda usar este equipo en aplicaciones de mantenimiento artificial de la vida, donde se puede esperar razonablemente que su falla cause la

falla del equipo de mantenimiento de la vida o que afecte de manera importante su seguridad o eficiencia. No use este equipo en presencia de mezclas

anestésicas inflamables con aire, oxígeno u óxido nitroso.

Los racks SmartRack acomodan todos los equipos

estándar para montar en rack de 19 pulgadas,

independientemente del proveedor, y se envían

completamente ensamblados para una

implementación rápida y fácil. Tienen gabinetes

adaptables, de alto rendimiento, con alturas de

25U, 42U y 48U, con o sin paneles laterales.

Disponemos de varios modelos con pálet contra

golpes integrado que permiten que los

revendedores, integradores y clientes de la

empresa preconfiguren los equipos y reenvíen los

racks al sitio de instalación final.

Los SmartRack tienen profundidades de montaje

variables, ideales para servidores. Las herramientas

de combinación integradas permiten la expansión

económica, ordenada y eficiente. Los gabinetes

incluyen puertas y paneles laterales de liberación

rápida para el mantenimiento cómodo y puertas

frontales y traseras divididas (modelos específicos)

para mejorar el acceso y contar con requisitos

reducidos de despeje. Las puertas de acceso

frontal son reversibles para flexibilizar la instalación.

Las puertas y los paneles laterales se pueden

bloquear.

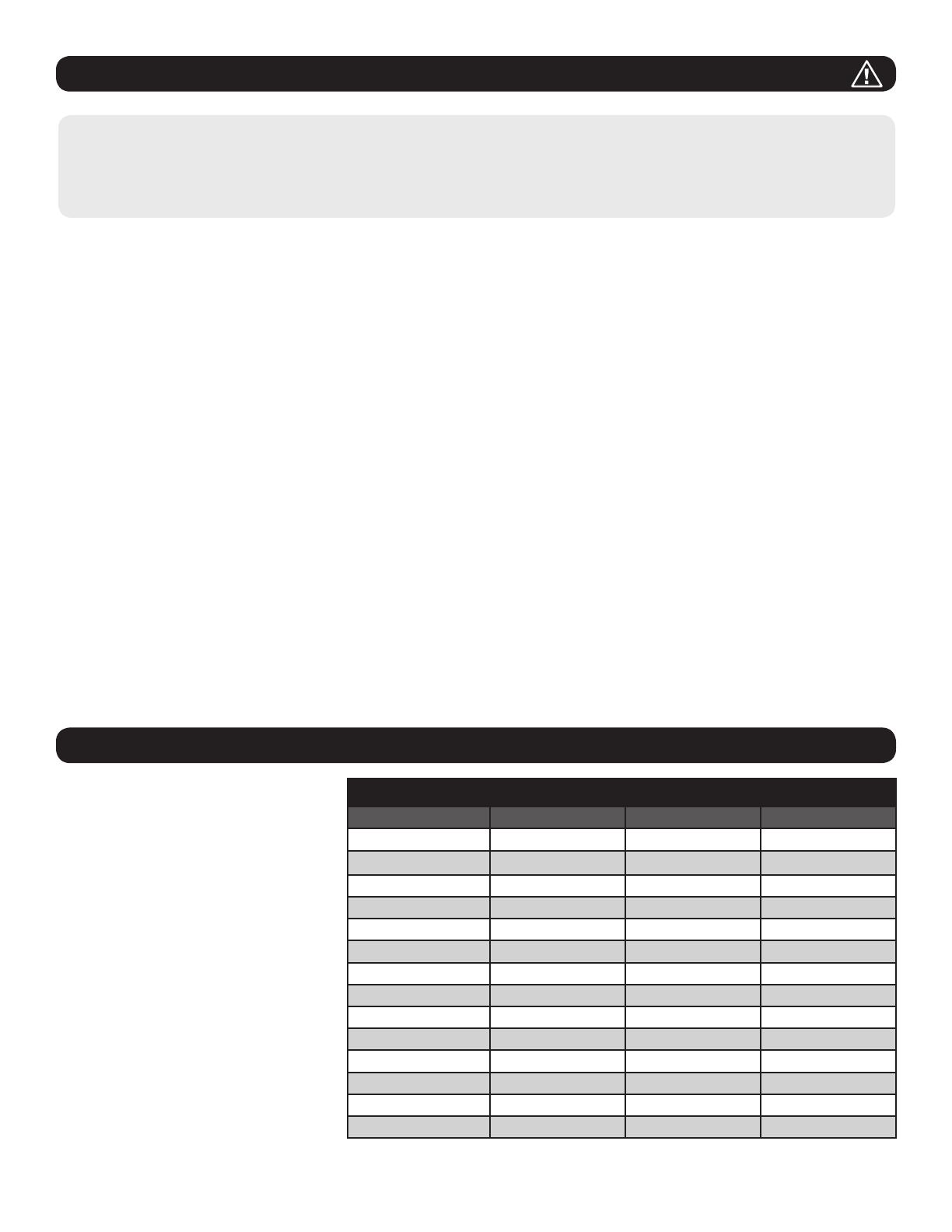

Racks SmartRack disponibles

Model # Altura Panele Pálet c/golpes

SR25UB 25U Sí No

SR25UBEXP 25U No No

SR25UBSP1 25U Sí Sí

SR25UBEXPSP1 25U No Sí

SR42UB 42U Sí No

SR42UBCL 42U Sí No

SR42UBEXP 42U No No

SR42UBSP1 42U Sí Sí

SR42UBEXPSP1 42U No Sí

SR48UB 48U Sí No

SR48UBCL 48U Sí No

SR48UBEXP 48U No No

SR48UBSP1 48U Sí Sí

SR48UBEXPSP1 48U No Sí

Consulte la sección Especificaciones para obtener más información.