GB

9

Wash cycles and functions

Wash functions

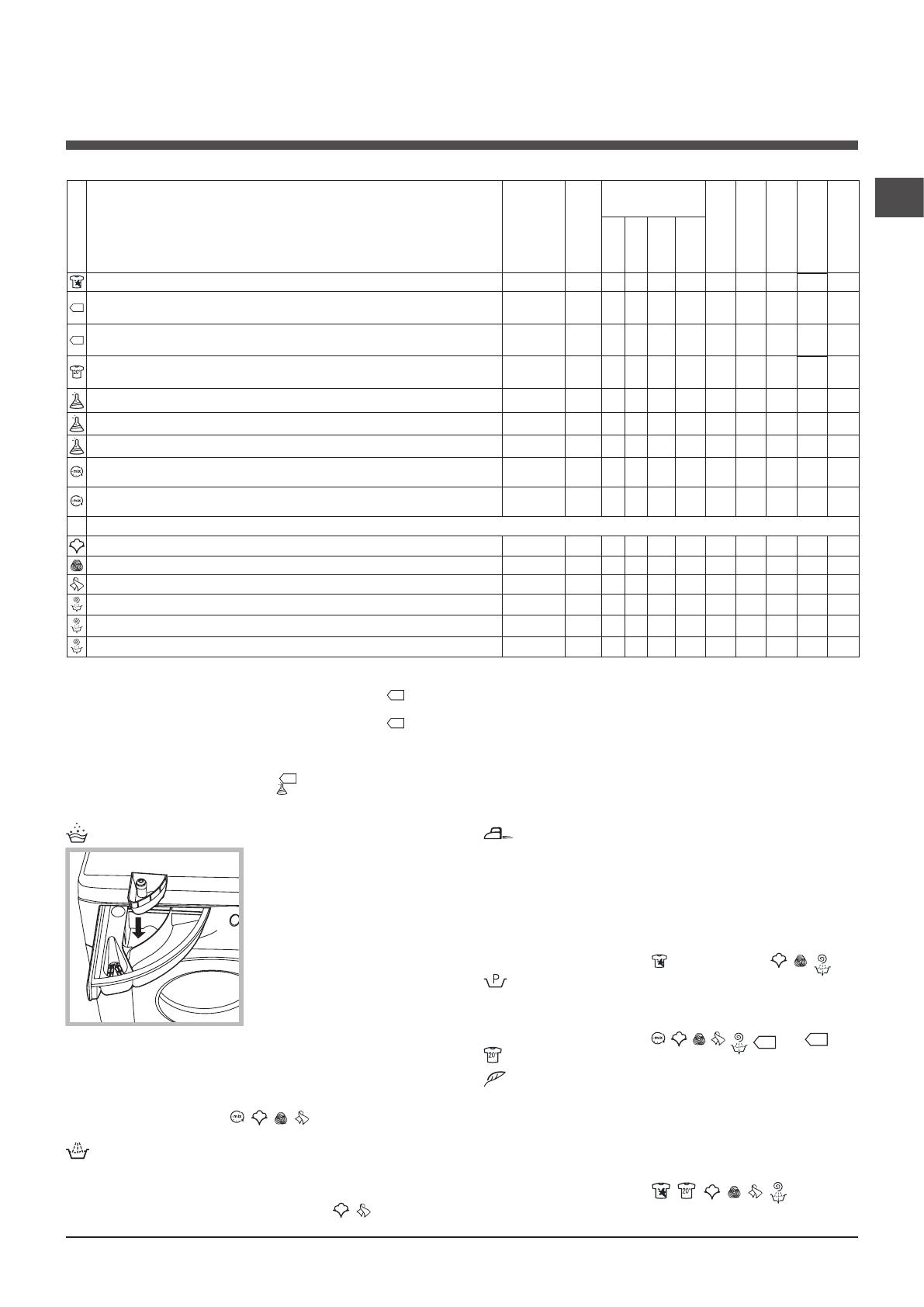

Super Wash

This option offers a high-

performance wash due to the

greater quantity of water used

in the initial phase of the cycle,

and due to the increased wash

cycle duration, is particular-

ly useful for the removal of

stubborn stains. It can be used

with or without bleach. If you

desire bleaching, insert the

extra tray compartment (4) into

compartment 1. When pouring

in the bleach, be careful not

to exceed the “max” level marked on the central pivot (see

figure). To bleach laundry without carrying out a full wash

cycle, pour the bleach into the extra compartment 4, select

the “Rinse” cycle and activate the “Super Wash” option.

! The use of extra compartment 4 excludes the “Pre-wash”

function.

! It cannot be used with the , , , , “Fast Spin Cottons”,

“Pump out”.

Extra Rinse

By selecting this option, the efficiency of the rinse is increased

and optimal detergent removal is guaranteed. It is particularly

useful for sensitive skin.

! It cannot be used with the “Fastwash 30’”, , , “Fast Spin

Cottons”, “Pump out”.

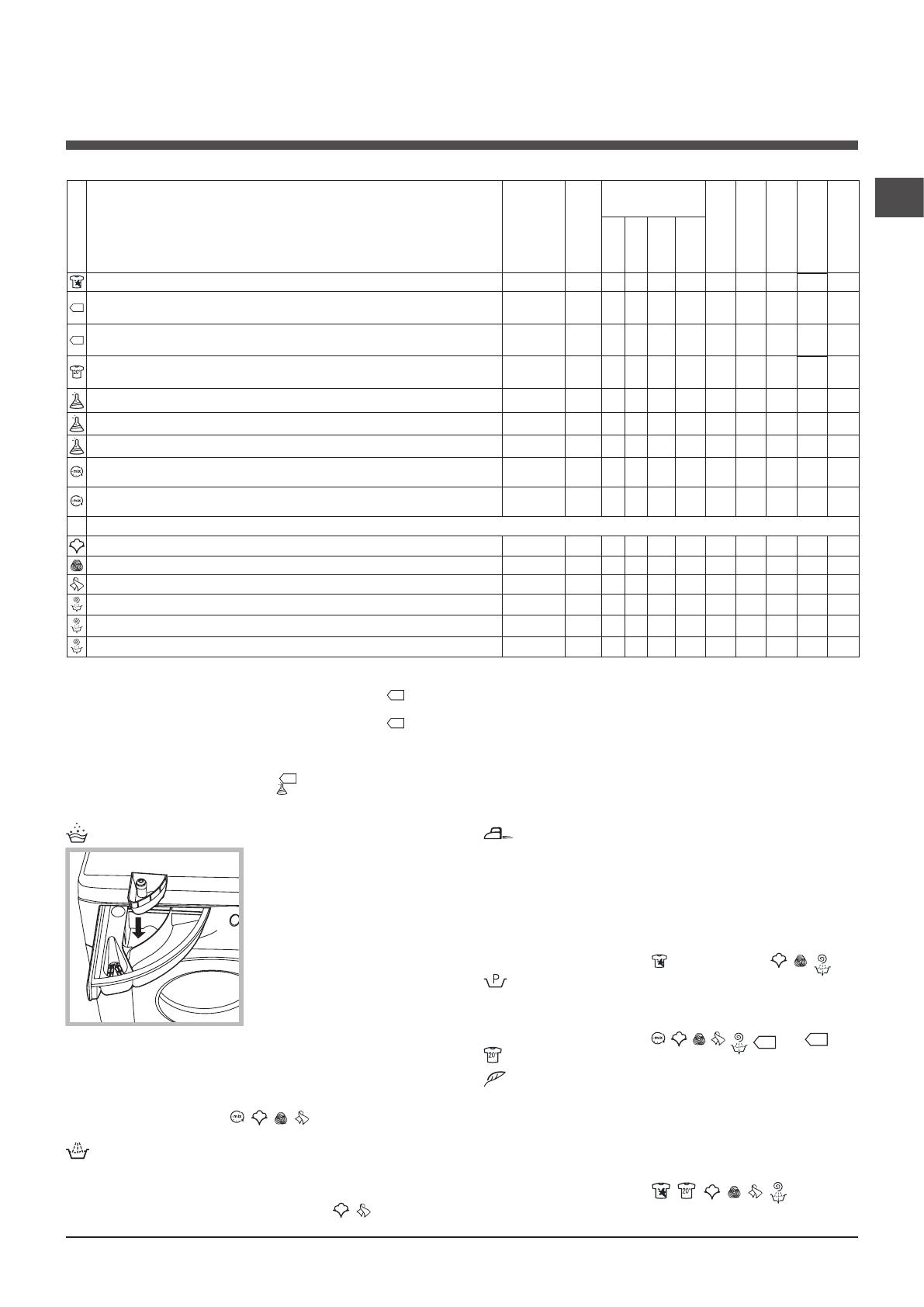

Table of wash cycles

Easy Iron

By selecting this function, the wash and spin cycles will be modified

in order to reduce the formation of creases. At the end of the cycle

the washing machine will perform slow rotations of the drum; the

EASY IRON and START/PAUSE indicator lights will flash (orange)

and the text “END OF CYCLE” will appear on the display. To end

the cycle, press the START/PAUSE button or the EASY IRON

button. To drain the water so that the laundry may be removed,

press the START/PAUSE button or the EASY IRON button.

! It cannot be used with the , “Fastwash 30’”, , , .

Prewash

If this function is selected, the pre-wash cycle will run; this is

useful for removing stubborn stains.

N.B.: put the detergent in the relevant compartment.

! It cannot be used with the , , , , ,

(60°), (40°),

.

Eco Wash

The Eco Wash function saves energy by not heating the

water used to wash your laundry – an advantage both to the

environment and to your energy bill. Instead, intensified wash

action and water optimisation ensure great wash results in the

same average time of a standard cycle.

For the best washing results we recommend the usage of a

liquid detergent.

! It cannot be used with the , , , , , .

Wash cycles

Description of the wash cycle

Max. temp.

(°C)

Max. speed

(rpm)

Detergents

Max. load

(kg)

Residual dam-

pness %

Energy con-

sumption kWh

Total water lt

Cycle duration

Prewash

Wash

Fabric

softener

Bleach

Anti Stain

40° 1400

4 - -

-

180’

Standard Cotton 60° (1) (1st press of the button): heavily soiled whites and

delicate colours.

60°

(Max. 90°)

1400

(3)

7 53 1,10 52,5 190’

Standard Cotton 40° (2) (2nd press of the button): lightly soiled whites and

delicate colours.

40° 1400 -

7 53 0,99

82

185’

Standard Cotton 20° (3rd press of the button): lightly soiled whites and

delicate colours.

20° 1400 -

7 - -

-

170’

Synthetics Resistant (1st press of the button): heavily soiled resistant colours. 60° 800

3 44 0,93 47 110’

Synthetics Resistant (4) (1st press of the button): lightly soiled resistant colours. 40° 800

3 44 0,57 46 95’

Synthetics Delicate (2nd press of the button): lightly soiled resistant colours. 40° 800

3 - - - 70’

Fastwash 60' (1st press of the button): to refresh normal soiled garments quic-

kly (not suitable for wool, silk and clothes which require washing by hand).

60° 1400 -

- 3,5 53 0,81 40 60’

Fastwash 30' (2nd press of the button): to refresh lightly soiled garments quic-

kly (not suitable for wool, silk and clothes which require washing by hand).

30° 800 -

- 3 71 0,15 35 30’

M

My Cycle: allows for any wash cycle to be stored.

Anti Allergy

60° 1400 -

- 4 - - - 195’

Woolmark Platinum (Wool): for wool, cashmere, etc. 40° 800 -

- 1,5 - - - 70’

Delicates

30° 0 -

- 1 - - - 80’

Fast Spin Cottons (1st press of the button) - 1400 - - - - 7 - - - 16’

Rinse Cottons (2nd press of the button) - 1400 - -

7 - - - 36’

Pump out (3rd press of the button) - 0 - - - - 7 - - - 2’

The length of cycle shown on the display or in this booklet is an estimation only and is calculated assuming standard working conditions. The actual duration can vary according to factors

such as water temperature and pressure, the amount of detergent used, the amount and type of load inserted, load balancing and any wash options selected.

1) Test wash cycle in compliance with directive 1061/2010: set wash cycle 60°C (1st press of the button).

This cycle is designed for cotton loads with a normal soil level and is the most efficient in terms of both electricity and water consumption; it should be used for garments which can be

washed at 60°C. The actual washing temperature may differ from the indicated value.

2) Test wash cycle in compliance with directive 1061/2010: set wash cycle 40°C (2nd press of the button).

This cycle is designed for cotton loads with a normal soil level and is the most efficient in terms of both electricity and water consumption; it should be used for garments which can be

washed at 40°C. The actual washing temperature may differ from the indicated value.

3) At 60 °C the “Prewash” function cannot be selected.

For all Test Institutes:

2) Long wash cycle for cottons: set wash cycle 40°C (2nd press of the button).

4) Long wash cycle for synthetics: set wash cycle 60°C (1st press of the button); temperature of 40°C (press TEMPERATURE button).